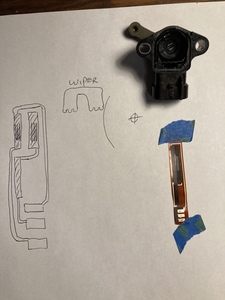

I'm struggling to reproduce a repair trick that a kid in Moscow did on his Spyder. Triz said he has done it also. The position sensors crap out, send jumpy voltage to the TCU and it goes nuts. The "fix" is to remove the conductive strip from inside the position sensor(s), scrub the surface with a pencil eraser, then restore the conductive surface with a #2 pencil.

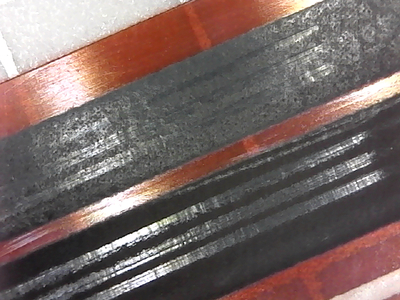

So I have disassembled a bad sensor, and I'm scrubbing. Any ideas if I'm removing bad crap from the conductive surface? Are the original shiny tracks just polished conductive stuff? Or are the shiny tracks a build-up of crud to be removed? What's coming off onto my eraser, good stuff or bad stuff?

Any help is appreciated!

The upper track has been scrubbed with the eraser. The lower track is "as removed".

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Hi Cyclehead . . . Please remember I know nothing about any of this kind of stuff. There's my legal disclaimer. Sometimes the contacts on the ink cartridges in my printer get grunged-up with grunge you can't even see and prevent the printer from printing. I used to replace the cartridge and discard the non-working one. Then I started using the eraser trick and most times that would do the trick to get the ink cartridge working again. I got to where I would automatically do the eraser trick when installing new cartridges with fewer breakdowns. Don't know if that helps any, but thought I'd pass it along, just in case.

I'm no expert but I'd say you might be on to something. I made a transistor with a sheet of paper and a pencil once though if that does anything for you lol. Hope it works.

Beejeezus, and then am I struggling with the idle being too high. I am sériously in awe 😲

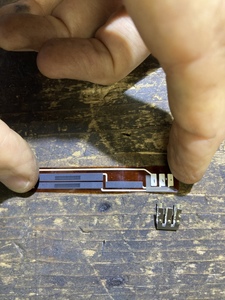

I believe that’s the variable resistance strip which I think is graphite. That’s also the part that gets contaminated with brake fluid. I think it just washes away the graphite. My guess is some of the wiper material gets left behind and imbeds in the graphite making it shiny. Erasing it might be enough although it might remove some of the resistor. Don’t see the pencil lasting long but it’s worth a try. I was amazed at how delicate the wiper is and how it barely touches the resistor.

They make a spray graphite in a can. You may need to bake it at 200 degrees for an hour or 2.

I have done this method to replace the graphite coatings on rods.

They make a spray graphite in a can. You may need to bake it at 200 degrees for an hour or 2.

I have done this method to replace the graphite coatings on rods.

“Dry film lube” correct? I’m pretty sure the circuit is printed on Mylar sheet. Can Mylar take the heat of baking?

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Yes dry film, maybe try 100 degrees for 3-4 hours. Like slow roasting.