My parking brake cable started seizing. My car has seen snow exactly ONCE in its life and never salt. WTF. I tried forcing lube into the housing. No joy. So I went for distructive disassembly. Holy crap that cable was stuck hard! I had to rig a spring compressor backwards to extract the cable and it fought me all the way! I expected to see snarled cable strands and corrosion. Nope. Plastic encased cable looks perfect!

What the heck is grabbing the cable!!!!!

I’m off to burn the plastic casing off the cable, goop it up with grease and reinsert it. I hope to get the cables working again without replacing or dropping the gas tank. Wish me luck.

Update for future reference.

This works! The most difficult part is pulling the seized cable out of the housing. If you attempt to duplicate this idea, make sure you have a plan how to extract the old cable if it has seized. It is very very hard. You can’t just yank on the inner cable or you’ll rip the housing from the car and stretch it. So you have to hold the cable housing, while you pull on the inner cable. My cobbled “puller” made from a spring compressor was not an elegant solution. It took four hands to keep it from flipping inside out while hitting the screw jack with an electric impact hammer. The opposite side (not seized quite so badly) was slightly easier.

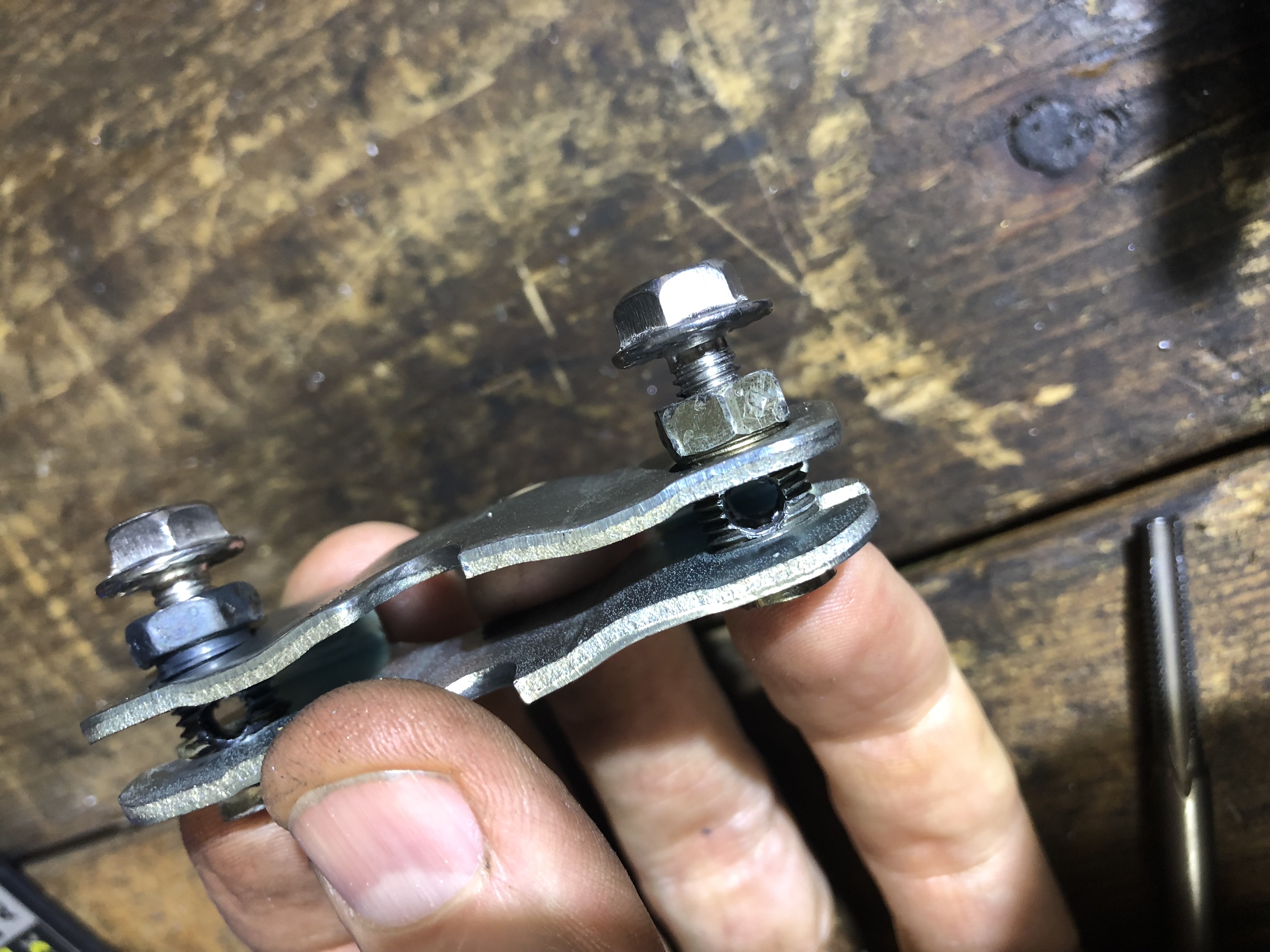

The only other tricky part is fabricating a screw-thread-fitting to grab the cable end, after melting off the lead ball. I made mine from two hydraulic line flare fittings. It was hard to drill the hole in the side for the cable, as the drill bit kept skidding off center. The ID was just right for an M6x1.0 thread. The home made cable end is a one-time deal since it smushes the cable strands into a tangled mess. If you ever try to remove the threaded cable end, the cable strands will never thread through the hole again.

One more caution - when you grind the lead ball-end smooth so it can be removed through the housing, try not to cut any steel cable strands. If it’s not smooth, it will snag when you push the cable back into the housing.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Cable end.

Okay, I goofed. This one is backwards! The cable goes perpendicular to the axis of the fitting, and the pinch screw needs to thread into the center hole of the fitting (swap everything 90 degrees).

I just tapped the center hole M6x1.0 and it worked.

Later pictures are correct.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Hah! It worked. Burning the plastic sheathing off the cable reduced the cable diameter from .166 to .133. So I gained .030 room for the cable to slide. I lubed it up with lithium grease and poked it through! I need to finish my homemade cable end made from a brake line fitting. If I’m lucky I’ll have parking brakes fixed .... on a weekend .... when dealers are all closed...and I’m too lazy to drop the fuel tank.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Melting the lead tip off the cable end...

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

On the second cable I perfected the plastic burning technique. You play the flame along the cable for about 10 inches until the Cable gets so hot that the plastic is burning by itself, then move onto the next section. Don’t let the cable gets so hot that it glows cherry red or it will curl up and ruin the heat treat.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Good stuff, nice pics and when your done I sure it will be better than new. BTW was that one time in the snow the COTM picture?

Good stuff, nice pics and when your done I sure it will be better than new. BTW was that one time in the snow the COTM picture?

That was the one time snow. We’ll be due for another one in about 40 years.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

After removing both cables from my car that were completely frozen, I see no reason they should have gotten stuck. This makes me question the forum lore, that freezing water causes them to seize. I wonder if it’s just coincidence that folks discover their brake cables are frozen on a snowy day. Or does cold weather make the plastic linings in the cable and housings seize? Maybe a plastic lining contracts and grabs the inner cable? Either way it’s not corrosion that’s causing the problem!

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Don't think it's freezing water. I test drove one that was in the garage for a long time (battery had died) and the parking brake was stuck. Might just be temperature related.

Hah! It works! Money spent = $0. Time spent, a whole freakin afternoon.

Next time, I wish I had installed the cable end pinch bolts on the bottom. Where I put mine on top come close to fouling the shift cables. But nothing a few tie wraps won’t fix.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

I love it! What ingenuity.

Is the plastic sheathing that well bonded to the cable that it can’t be sliced and peeled off or would a heat gun do the trick? If it’s PVC, maybe soaking the cable in acetone would soften it up?

The plastic coating was not like a tube. It was melted into the cable strands like it had been dipped maybe. I didn’t experiment with chemicals. I immediately thought of fire to remove the coating. I noticed the coating caught on fire as I was melting the lead cable tip. But oxyacetylene torch worked a charm.

Heat gun would definitely not be hot enough. Propane torch would work, but it will be very slow.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.