A customer sent me these pictures and i really wanted to share them with you guys. I asked him for permission and he said yes and also sent me a ton of more detailed pictures so i'm excited to share them with you guys.

A few years ago i made a very comprehensive 2AR-FE swap kit for the Spyder, it makes 205rwhp and personally i think that's a really great amount for a street car and even for a race car. I race mine at that power level and have an absolute blast.

But with that said, i *CONSTANTLY* get requests for the 2GR-FE.

So here's the thing, a 2GR-FE swap will never be a bolt-in swap. Even if it fits in the engine bay and bolts right in, you absolutely will need an access panel to service the front coils at a minimum because this motor unfortunately is known to blow coils semi regularly. While not as critical it would also be a really wise idea to make an access panel for the alternator. because the bracket on the 2GR hugs the top and the bottom of the alternator so it has to move away from the motor by about 2" before you can remove it.

So for all of those that agree with those above statements, we can continue with the good news.

The motor fits with my 2AR-FE swap kit a lot better than i expected.

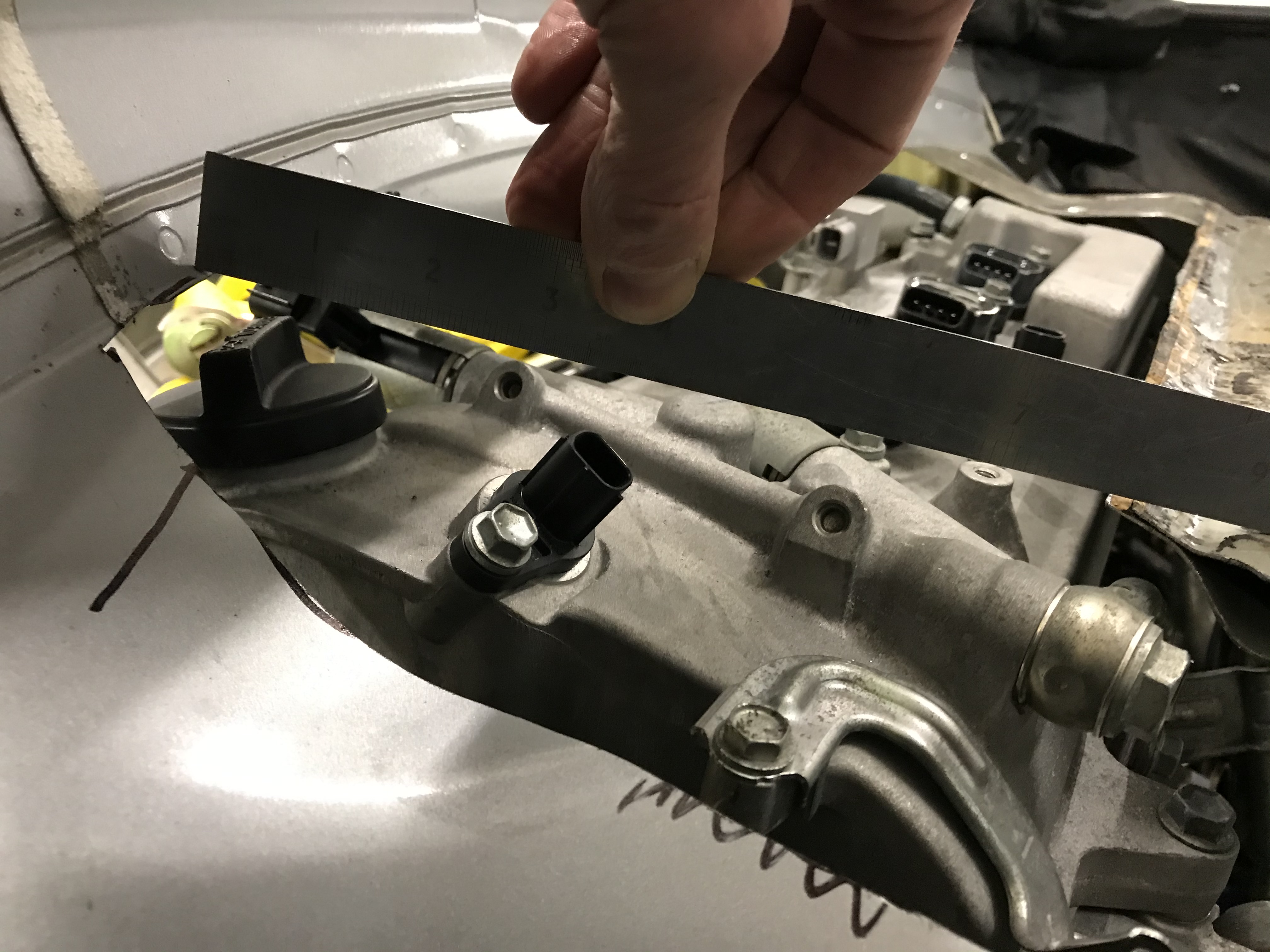

The alternator actually fits if it wasn't for the electrical connector. (just barely and does not leave room for engine movement but it technically fits)

So with a small access cover there, it does not even have to be as big as the hole pictured and would only need 10-15mm of clearance and a little extra around the connector:

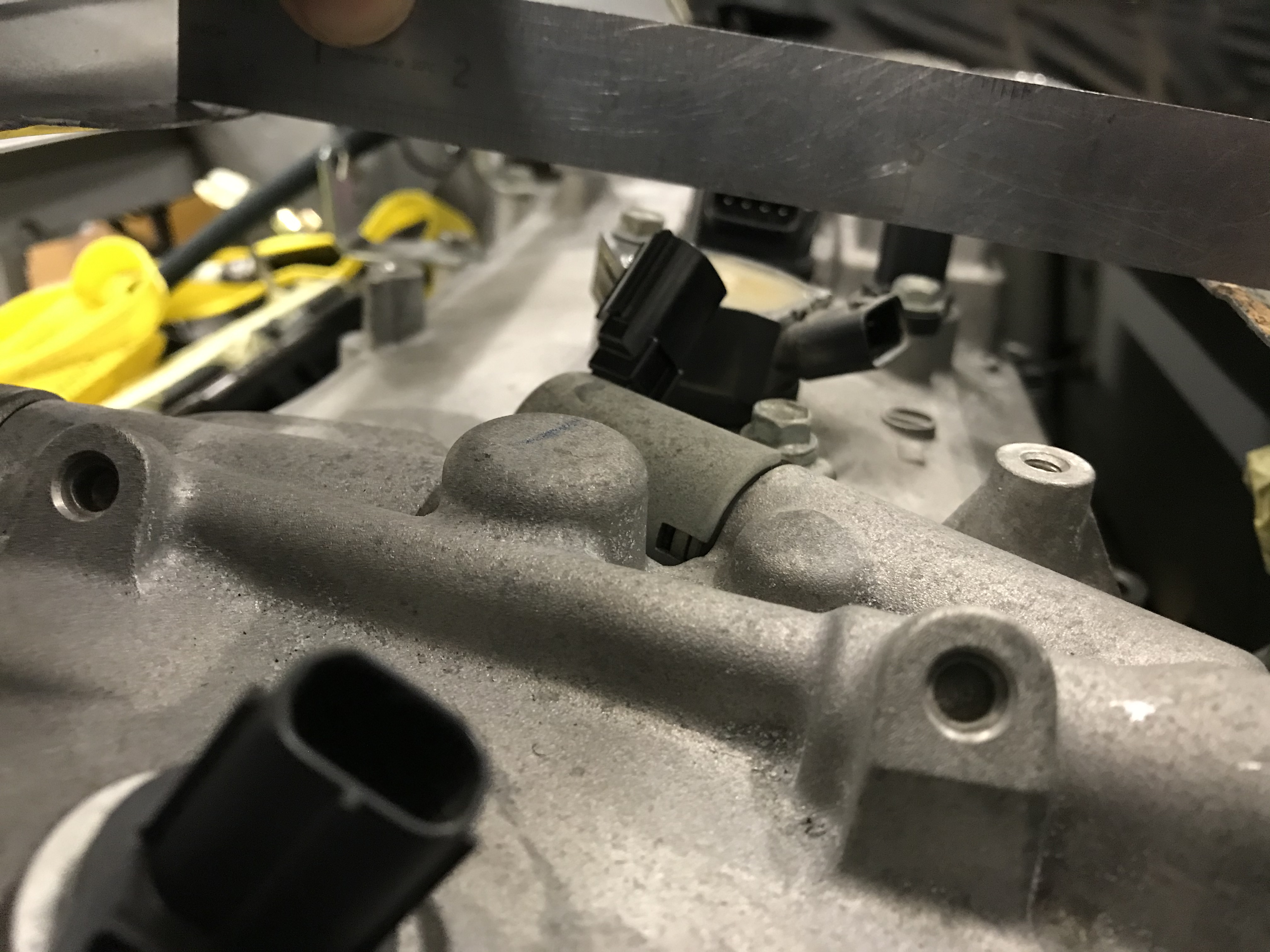

Then, from the top you can see the coils clear. You'll want the service cover there too but it does not need to add clearance. that same cover will allow access to the dipstick.

The front vvt-i connector won't clear but they are actually interchangable. just use a different vvt-i solenoid there with a plug that goes towards the back of the car instead of upwards:

The rear VVT-I oil line is the worst interference but it's in an area that does not matter so this area can be built up.

Filling the oil will be damn near impossible in the stock location. I think the best solution there is to just add a different fill location. The timing tensioner cover would actually be a really good candidate, it's steel and goes right down to the crank case so you could weld a filler neck on there. you could use something as small as a transmission style fill tube and just use a funnel. so what if an oil change takes 5 minutes longer for the oil to go in?

In this case he used my SW20 mount and made custom side chassis brackets. This is an area where if i supplied a part it could be much easier of course. There are also other alternate solutions possible here that use the stock Spyder isolator and just a solid bracket: (and yes, i agree this chassis bracket looks a little thin, we don't need to talk about this in this thread, it will just muddy the waters and does not affect what i'm trying to say here)

Now there is currently no header that fits as far as i know but one of the biggest triangular merges and it just barely clears. This is with 2" primary pipes. if you used something more resonable like 1-5/8" primary pipes like i do on my current 2GR headers it would fit with plenty of clearance. And yes, you will want a shield on that clutch line or relocate it.

All this means that all my transmission mount brackets can be used, my cheap axle solution can be used, my body controller can be used (it will drive the coolant gauge, alternator light and oil pressure light and also control the cooling fans since the 2GR ECU won't do it), the shift linkage stuff which really simplifies a complex part of the swap, the DBW pedal mounting, the tuned ECU, the two pre-made wiring harnesses (though the 2GR ECU side will need repined slightly, no big deal i can help), even the ECU brackets to mount it in the engine bay nicely can be used and finally the MAF pipe to make the whole thing run nice and smoothly. The MAF pipe bracket may be usable also but it may not place the pipe at the right angle. I haven't checked that yet.

A little bit of ground clearance is lost but the 2GR is actually not as deep as the 2AR so it isn't a very big loss.

All the parts are available today at www.FrankensteinMotorworks.com

Thanks for sharing, Marc. I went to your website and realized, "oh, you're the guy that put a radial airplane engine in a mkIII!" I remember you sharing that on SC a few years back and your experiences with the 24 Hours of Lemons. I really enjoyed your stories of nation-wide collaborations to engineer parts just to be able to cobble all those parts together and the commerodery of like-minded Frankenstein gearheads across the continent. I bow to your greatness.

Yeah, that's me. it was actually an MKII:

That kind of stuff explains the name significantly more than the swap parts i sell for MR2s 🙂

It like you nearly killed two birds with one researched swap.

These two engines look like they might be leading the way in the future. I wouldn't have thought that since the 2ZZ swap is a lot of value and time saved by being easy but not so anymore especially seeing how many new 2ZZ swappers having all kinds of issues with worn old abused engines turning up or possibly the rubber seals drying out giving way to all kinds of vacuums leaks and other issues. There is nothing better then drawing from a bigger pool of modern Toyota engines that has all the power and reliability.

I may be crazy, but I think my oil filler cap is on the aft (RH) bank. Pics show filler on the forward/LH bank. Are there different rocker covers available on 2GR engines? - yeah never mind. Mine is in the same location, it’s just my engine mounts have the engine rotated further aft so my filler cap is clear of the engine compartment box beams. I think my installation has the engine slightly off level, rotated towards the rear. I can remove my alternator with the engine installed. But it’s very tight.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

It like you nearly killed two birds with one researched swap.

These two engines look like they might be leading the way in the future. I wouldn't have thought that since the 2ZZ swap is a lot of value and time saved by being easy but not so anymore especially seeing how many new 2ZZ swappers having all kinds of issues with worn old abused engines turning up or possibly the rubber seals drying out giving way to all kinds of vacuums leaks and other issues. There is nothing better then drawing from a bigger pool of modern Toyota engines that has all the power and reliability.

As long as there are 2zz engines in good shape it'll be impossible to beat the price of that swap with anything else. it's just such a simple swap. But if what you're saying is right then yeah, the 2AR with all the stuff i've made really is a simple swap and is quite economical to do. Bolt-in and plug & play for $5k is really low and with engines at the $300 price point you can even experiment with boost without feeling too bad if you blow an engine.

As for the 2GR, it helps i already have the MKII parts made, especially the ECU but the fitment in here is a bit lucky. I did not expect it to fit nearly as well as it does.

I may be crazy, but I think my oil filler cap is on the aft (RH) bank. Pics show filler on the forward/LH bank. Are there different rocker covers available on 2GR engines? - yeah never mind. Mine is in the same location, it’s just my engine mounts have the engine rotated further aft so my filler cap is clear of the engine compartment box beams. I think my installation has the engine slightly off level, rotated towards the rear. I can remove my alternator with the engine installed. But it’s very tight.

I had gotten all excited when i saw your original post. I did not know of any 2GRs with the filler on the rear valve cover but it would have been really neat.

A bit more rotation could certainly help a 2GR specific mount set. I also don't know what transmission you're using but the EB60 is about 5mm from hitting the crossmember in the current position. If you used an E153 and modified the crossmember it's likely your engine is a touch further back.

If you have engine bay pictures, especially of the tight spots to share for an alternative fitment that would be great to share (or just link to where they are, that would be appreciated also.)

I’ll get some pictures. I’ve been needing to document how USPSPRO did the installation.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

Awesome, that would be appreciated.

Which transmission is your swap using? E153?

I have s51 transmission with a heavily butchered crossmember. I welded a beefy box beam onto the aft side of the crossmember to restore the net section. No problems with the crossmember for 120k miles! I only broke one S51 so far - broken teeth on the ring gear.

update: Lots of photos and full description of USPSPRO’s homemade swap... here.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

This is now getting turned into a video series, you can get see the playlist here: