I spent some time in the shop this weekend and fabricated Third Brake Light Visors (TBLV) out of HDPE. I have no idea if these are going to work out, but am shipping to 3 community members -- Cyclehead, Dev and Haloruler64 -- tomorrow who will test the product to see what they think and how it holds up.

In the pictures below you will see a white fiberglass TBLV that I purchased from another member back in 2009. You will also see a black TBLV that I fashioned this weekend. I have provided different views so we can make comparisons and look at the differences. The Black HDPE TBLV has about a 1/4 inch overhang so it gives a "frenched-in" look to the third brake light. I have also crafted the HDPE TBLV so that it sits a little more flush (it is not flush) than the fiberglass version sits.

Again, I have no idea how these prototypes will work out. I am inviting the community members who are testing the product to post, here in this thread, pictures and feedback -- positive and/or negative -- about the prototypes which will inform my decisions on whether or not to put these into production. This version of the TBLV may be a total flop. Time and the honest feedback of our testers will tell. Thank you to Cyclehead, Dev and Haloruler64 for generously consenting to test these. Your input is truly appreciated.

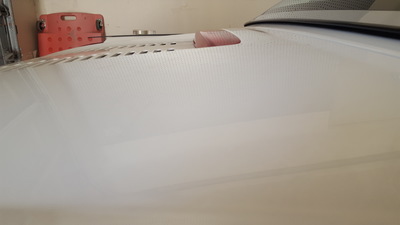

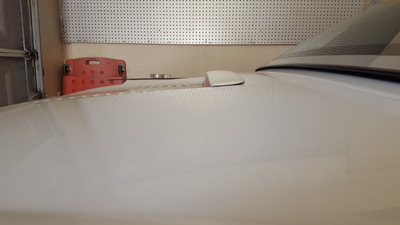

Side view with no visor

Side view with fiberglass visor

Side view with HDPE visor

Other views

They sure look slick. Time to polish up my third brake light to make it look respectable.

2000 Toyota MR2 Spyder, 2021 Lexus UX 250h F Sport

Very good work UM.

Here is my feedback.

I think you got the edges on the back and sides nicely done.

All it needs is more overhang to get the brake light in the shade and recessed it a little. This is what pulls of this look.

I also vote for the "Frenched In" or overhang model. Having the light somewhat enclosed adds, IMHO, a more finished appearance.

Might as well ask the question that is sure to be on folks mind: What are you estimating actual selling price to be for this Nice-To-Have Mod?

Paul

UM prototype received today.

First off the piece including the material is much better than fiberglass. The thickness is just right.

Here is what I think could be revised.

As I suspected it's too small, almost forum fitted to the brake light.

1. The most rearward edge is bowed in the middle. It would be better if it had a straight edge.

2. the length needs to be longer so it covers the crease edge on the hood. I would say about 1/4 inch on both sides.

3. The width of the brake light needs to be wider so there is overhang. This will recess the brake light so its buried in the shade which hides the reflective part of the light so stray rays don't hit it.

Apart from that its very nice solid material. I have seen all version of this visor and I can say that this is the by far the best one that is the most true. It should leave a paint surface that will not have any optical blemishes.

Sounds great, Uncle Mush!

UM prototype received today.

First off the piece including the material is much better than fiberglass. The thickness is just right.

Here is what I think could be revised.

As I suspected it's too small, almost forum fitted to the brake light.

1. The most rearward edge is bowed in the middle. It would be better if it had a straight edge.

2. the length needs to be longer so it covers the crease edge on the hood. I would say about 1/4 inch on both sides.

3. The width of the brake light needs to be wider so there is overhang. This will recess the brake light so its buried in the shade which hides the reflective part of the light so stray rays don't hit it.

Apart from that its very nice solid material. I have seen all version of this visor and I can say that this is the by far the best one that is the most true. It should leave a paint surface that will not have any optical blemishes.

Thanks for the feedback, Dev. Much appreciated. I'm pretty swamped right now and through this weekend which means I won't even be able to go back out to the shop to work on this project until next weekend, at the earliest. If you don't mind, I'd like to give you a call sometime soon to get some more specifics of what I can do to make the changes you are recommending -- which I am happy to make and, again, grateful for your feedback. Maybe between now and then we might be able to get some more feedback from both Haloruler64 and cyclehead and then incorporate that, as well. I'm glad to hear that your initial impression is favorable. There are so many layers to testing new products, like this, but I think/hope we will be able to create something really good for the community. Thank you again for your support and collaboration.

I got mine today, but my dumb self left it at work when I was in a rush out to meet a Craigslist seller. I was at my grandma's house all evening anyway. I'll give it a shot tomorrow!

2000 Toyota MR2 Spyder, 2021 Lexus UX 250h F Sport

I temporarily laid mine in place yesterday, plus compared to my fiberglass version. I agree with Devs comments on the overall profile. More length to better match the sheet metal creases in the engine lid. And more width to make an overhang lip that will keep the Brake light shaded/recessed.

I want to hand work the transition radii all around the upper edges. Is there some way to make a uniform blend all around that edge?

I also want to see how it looks with the added space from 3m double sided tape. I recall the fiberglass version had a concave lower surface that allowed space for thick tape.

Any way to offer prepainted covers? For those of us who are paint-challenged?

I’d suggest buying a big roll of 3M tape and ship them ready to install - “peel and play”!

I’m excited to see this coming together. It will be a “must have” mod for all our new spyder owners.

I make Amateur Armrests - see the Commercial Forum. I also have SMT repair seals available.

I temporarily laid mine in place yesterday, plus compared to my fiberglass version. I agree with Devs comments on the overall profile. More length to better match the sheet metal creases in the engine lid. And more width to make an overhang lip that will keep the Brake light shaded/recessed.

Yes. I think I can make that happen. It's just going to take some time for me to get it right.

I want to hand work the transition radii all around the upper edges. Is there some way to make a uniform blend all around that edge?

I know what you are talking about and I think it is possible, but to make that happen it would take a lot more work to build a mold (secondary to the cutting/shaping process that already takes a bit of time to get right) and then a heat process to "emboss" the HDPE blank with that detail. That is something I can think about. My concern is that will at least double the amount of time to fabricate each piece and I don't know if I can make that cost effective. I even looked into having the HDPE blank (once we finalize the finished size) laser cut which would save a bunch of time in the fabrication process, but my provider for that service can only laser cut 1/16 inch HDPE because of the melting/burning aspects of the HDPE itself.

I also want to see how it looks with the added space from 3m double sided tape. I recall the fiberglass version had a concave lower surface that allowed space for thick tape.

Yes. This is definitely a concern, given the current design of this version. I am very interested to hear from y'all if the 3M tape does "hide", given the flat surface of the current test version. My fiberglass TBLV has a huge concave surface that was too concave, IMHO. I also didn't like the "hump" look of the fiberglass version and am trying to get away from that. If I have to fabricate an embossing mold like I described above, it might be possible to also emboss into the TBLV mounting surface a small "channel" that would help to conceal the mounting tape. I would just have to play around with it to see if I can make that happen and I am not sure I have the skill required to do that well. Another option would be for me (or the end customer) to use a drum sander in a Dremel to route-out a small ditch for the tape to hide. Perhaps I could build a special jig and use a router to carve out such a channel. Those are just some random thoughts for the moment. My hope (which may be unrealistic) is that once I get the shape/size finalized, hiding the mounting tape won't be an issue because of the low profile of the finished piece.

Any way to offer prepainted covers? For those of us who are paint-challenged?

I don't know about that. That's a huge investment in paint -- plus little likelihood it will ever match well -- especially after over a decade of sun fade to the original paint on the car and on a large horizontal flat surface on the car. Even 040 Superwhite (the fastest color Toyota ever produced) is subject to sun fade. To be taken into consideration under advisement . . .

I’d suggest buying a big roll of 3M tape and ship them ready to install - “peel and play”!

This is certainly an option. I have included mounting products with all the other parts I have created in the past.

I’m excited to see this coming together. It will be a “must have” mod for all our new spyder owners.

Thanks again, to our testers, for helping me on this project. I truly appreciate the collaborative process. Now, if I could just find some time to get back out in the shop to play . . .

I like it.

I'd also accept a delete if you had one. Not really concerned with if it's street legal to do or not.

Very nice assessment from Cyclehead.

I also had some concerns about the 3M tape thickness however I think it will ok once the visor has over hang that can cover up any thickness discrepancy.

All of this is a trade off and nothing made by us will be perfect particularly at its price point to be lucrative however I see the other side of the trade to be worth it being that the top side finish and material will be true.

When I last installed mine (from Dev’s batch years ago) and after I had it hydrocoated, I used some clear silicone instead of the 3M tape. It’s held on quite well and I don’t worry about someone trying to pull it off (well, mostly because no one here has Spyders) but you’d need a heat gun to break the seal. I might be interested in one as there’s a little surface defect on mine that didn’t correct with paint and the hydrocoating.

the point is, clear silicone once you’re ready to more permanently mount it might be a good way to go.

Very nice assessment from Cyclehead.

I also had some concerns about the 3M tape thickness however I think it will ok once the visor has over hang that can cover up any thickness discrepancy.

All of this is a trade off and nothing made by us will be perfect particularly at its price point to be lucrative however I see the other side of the trade to be worth it being that the top side finish and material will be true.

Yes. I found that to also be true with the fiberglass version I bought years ago. There were air pocket blemishes I had to fill and smooth before I could prime and paint, but I was willing to do that even at the $90 I paid for the product back then. btw, I don't know what they sold for originally. I bought my fiberglass TBLV used. I may not be able to mass produce a perfect product, but do hope to produce a better product that will fill the current void.